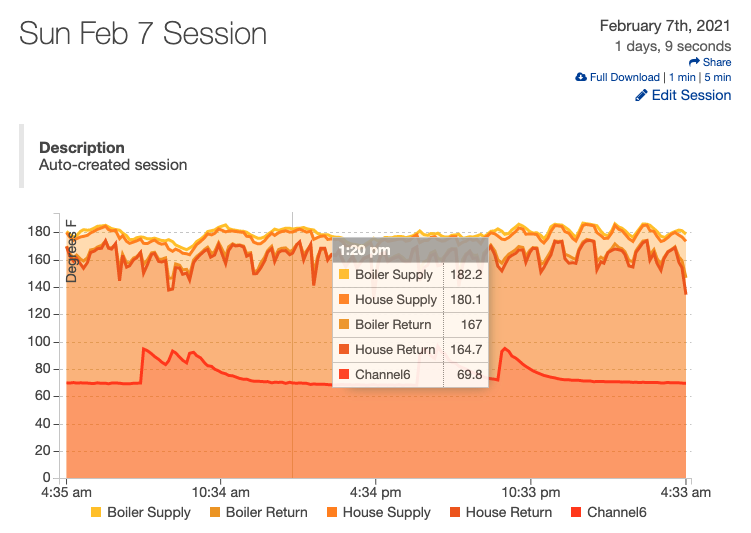

As shown in the previous case study, we weren’t capturing enough BTU’s from the outdoor wood boiler due to the small heat exchanger. This resulted in our circulator pumps running much longer throughout the day, which resulted in more energy usage. After we had upgraded our heat exchanger to a 80 plate, our temperature differential was much smaller, which resulted in zones getting to temp much faster = less electricity = cost savings. See below: